|

|

Variety of gas turbine |

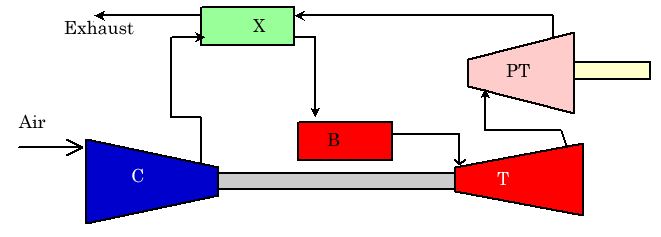

RegeneratorExhaust gases from gas turbines are very hot, over

500 degrees C, rich of energy and it is wasteful to throw away them. To

recover this exhaust energy, a regenerator was devised,. A regenerator

transfers the heat recovered from the exhaust gas to the compressor

discharge. This process allows considerable fuel saving and keeps the

exhaust gas temperature markedly below that of comparable to piston

engines.

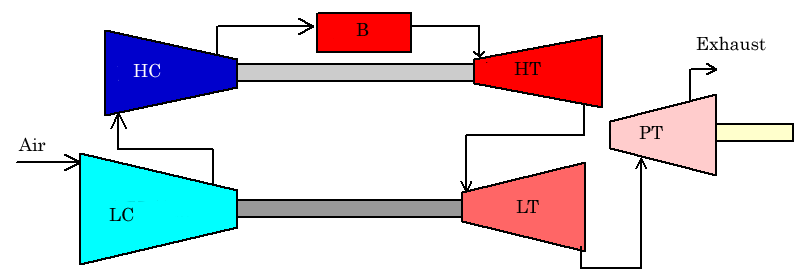

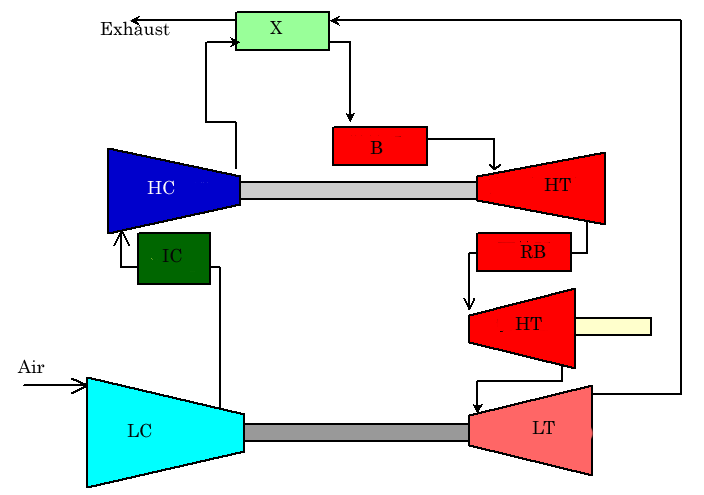

The regenerator is large in size, even larger and heavier than the gas turbine itself. So it is not suitable for aircraft applications. But in land and marine applications, fuel savings over 50% against a simple cycle gas turbine is very attractive. If a high pressure ratio can be achieved, this advantage fades away. But in small-sized or medium-sized gas turbine high efficient high pressure ratio compressor is not available and s regenerator is often used to save the fuel consumption. Three shaft gas turbineIf high efficient and high pressure compression cannot be achieved by single compressor, the dual stage compressor is often used. The next schema illustrates the gas turbine with high pressure compressor driven by high pressure turbine, low pressure compressor driven by low pressure turbine.

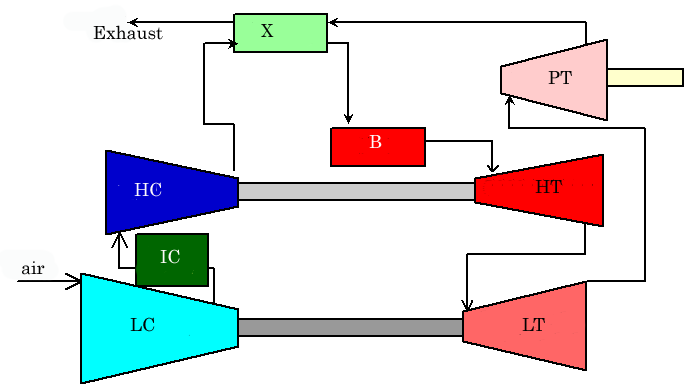

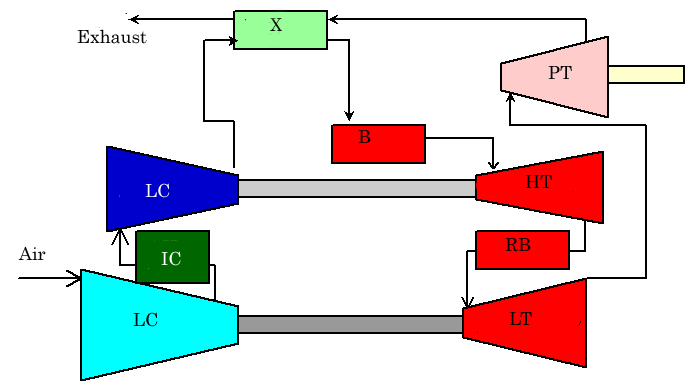

AGT1500 gas turbine used in the US Army's main battle tank, the M1A1 Abrams, has this arrangement. IntercoolerThe advantage of splitting into two compressors is that the compressed hot air can be cooled and compressing efficiency can be improved by inserting the intercooler between low pressure compressor (LC) and high pressure compressor (HC). But cooling compressed air means energy waste and to compensate for this loss, the heat recovery from exhaust gases is indispensable. The next schema shows the position intercooler (IC) is inserted. In this schema, a regenerator (heat exchanger X) is placed and in 60's this arrangement of gas turbine is often tried for heavy duty vehicles. Reheat combustorExhaust gas coming from high pressure turbine still has high pressure and high temperature and is oxygen rich. If a reheat combustor is placed here, more power can be derived. The next schema shows this.

You may think reheat increases the exhaust gas

temperature and is fuel wasteful, but when the temperature of

exhaust gas increases, the heat exchanger efficiently recovers the heat and

the compressed air temperature increases, less fuel is required at the

first stage combustor. to create the same amount of output.

This gas turbine is rated at 600hp, The peak efficiency for it is 37% - dramatically higher for its size than what competing gas turbines and diesel engines offered then.. Test runs are repeated but not mass produced.

|