|

|

Advancement of gas turbines |

Ceramic gas turbineA shortcut to improve the thermal efficiency of gas turbine is to rise the temperature of working gases. Theoretically, if the turbine inlet temperature (TIT) is raised to 1300 degrees of Celsius, the efficiency will be as same as that of diesels. The next schema shows the theoretical curves derived from calculations The thermal efficiency is represented on Y-axis and the pressure ratio is represented on X-axis. The solid curve represents the efficiency commonly used current gas turbines with recuperators. The solid curve on the left graph shows the performance almost same as that of the gas turbine currently sold by Capstones. Even such a small gas turbine of 30 kW class can achieve just as diesel equivalent efficiency if the TIT raises to 1300 degree s Celsius. But there are many difficulties to realize this. For recent large scale gas turbines, it is easy to achieve this temperature by using turbine blade cooling mechanism, which enables engines to operate at the temperature beyond the heat resistant temperature of turbine materials. But small gas turbines cannot have this cooling mechanism. Ceramics have been paid great attention as a turbine material. Heat resistive but fragile feature of ceramics has been the major obstacle to practical application of ceramics as high speed rotating turbine blades. In Japan and some other countries, this difficulty is partially overcome and experimental turbines is produced. In Japan, 100kW class output with 35% thermal efficiency for vehicle use and 300kW class with 42.1% efficiency gas turbines were made and tested. TIT reached 1350 degrees Celsius and 30 hour continuous operation was succeeded.. Super marine gas turbineThis is the project to use a gas turbine as a

propulsion engine of domestic vessel. Toxic diesel exhaust of diesel

propulsion vessels has been began to be considered as an environmental

problem. To resolve this, the development of high efficiency gas turbine

that can use the low cost fuel oil A was started. Turbine's

compact feature was utilized to provide a optimized hull shape

with low resistance, free layout of the engine room and more cargo

space. The high speed generator was simultaneously developed and compact

turbine electric propulsion system was constructed. The ship equipped

with this system was called "Super Eco Ship". The initial target

value of its thermal efficiency was 38 to 40% and 38.2% was achieved.

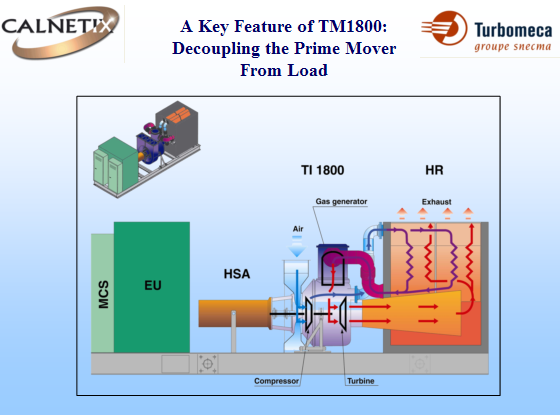

TM 1800 gas turbineTurbomeca developed the gas turbine for sea and land applications. Rail applications were also included. The structurally simple centrifugal compressor and single shaft mechanism were used to reduce the price and the recuperator was equipped to get good efficiency. The device served as a silencer and achieved reducing the size.

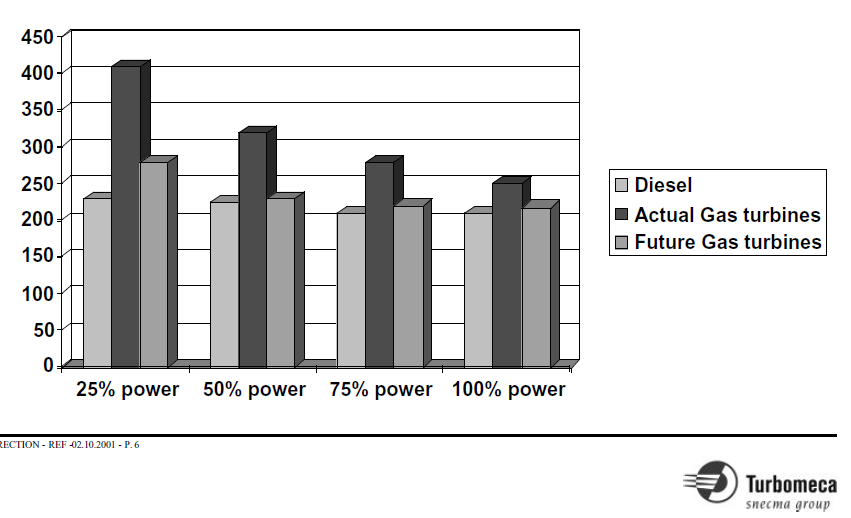

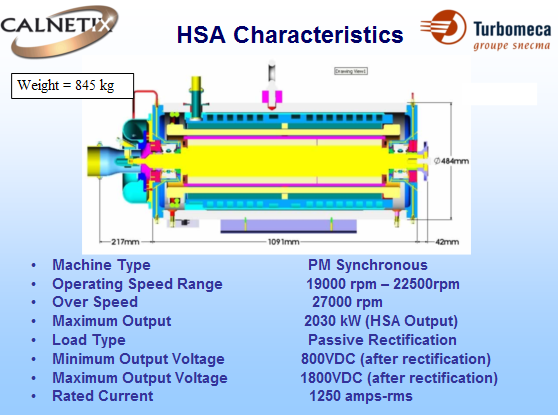

The fuel consumption ratio was 210 g/kWh, this was nearly the same as that of direct injection diesels. During a partial load, the fuel consumption worsened more than diesels but far more improves than Eurodyn the gas turbine in 1990s. The engine was designed to couple with the high speed generator from the beginning. Calnetix Technologies developed a permanent magnet alternator rotating at the speed of 20000RPM and only 845 kg weighing alternator produced 2000 kW electricity.

LV100 gas turbineThis gas turbine was developed for main battle tanks and Crusader artillery vehicles. Rated fuel consumption was reduced more than 25%, idle fuel consumption was reduced 50% comparing with AGT1500. Crusader artillery vehicles might be able to achieve 2 tons of weight reduction by replacing diesels to gas turbines. It is expected that if the high speed alternator is directly coupled to this engine, 1.1 tons weighing 1000 kW generator can be made. The test run was started and planned to start mass production in 2004 but financial difficulties disturbed the plan and postponed. LV50 gas turbine

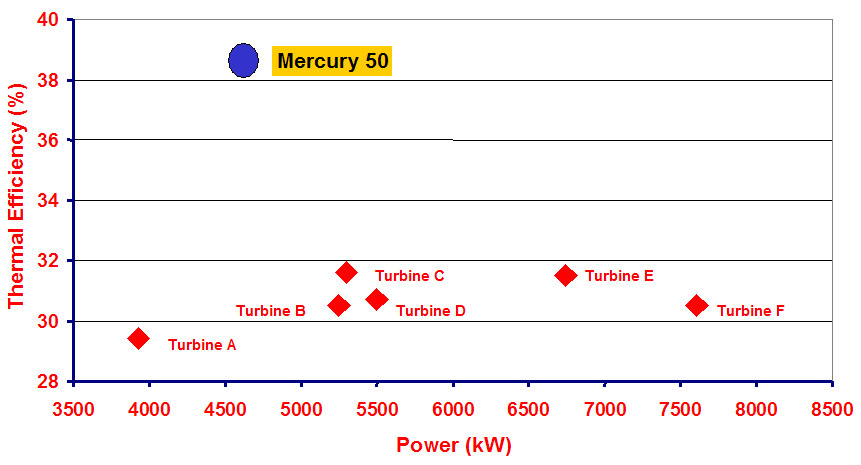

Mercury 50 gas turbineThis engine was developed in 1997 under the U.S. government national project called "Advanced Turbine Systems Program" started in 1992. The commercial production was started in 2003. The structure was single shaft recuperated gas turbine producing 4600 kW at 14168 rpm. The recuperated compact engine shown below could produce over 6000 horse power.

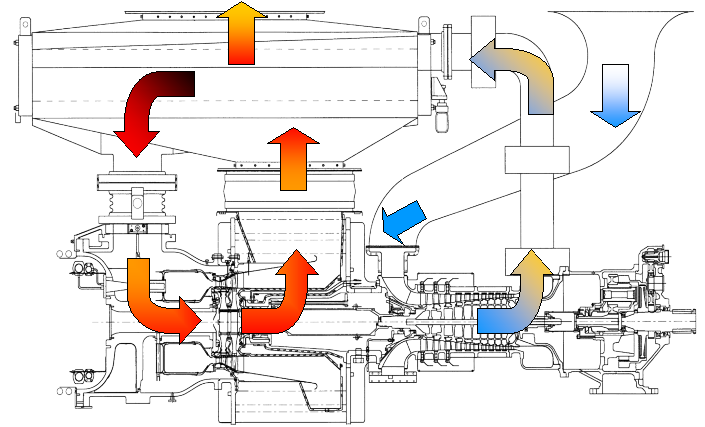

The next schema shows the cross section and the gas flow. Upper large space is recuperator to regenerate heat energy from the exhaust The pressure ratio is 9.9, relatively low due to the regenerative cycle.

The temperature of the exhaust reduced to 394

degrees Celsius by exchanging heat, considerably lower than simple cycle

gas turbines.

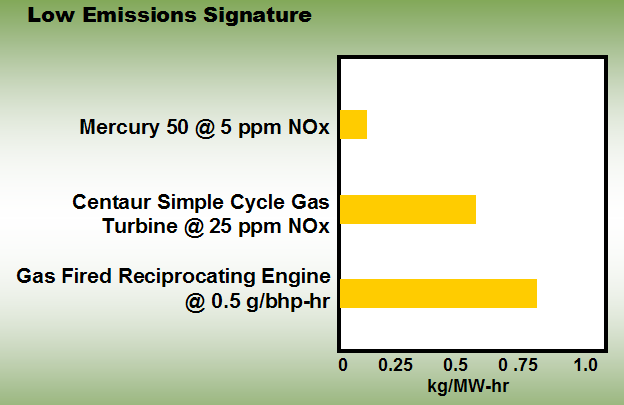

The next schema shows NOx emission comparing with other engines and reveals very low concentration of NOx.

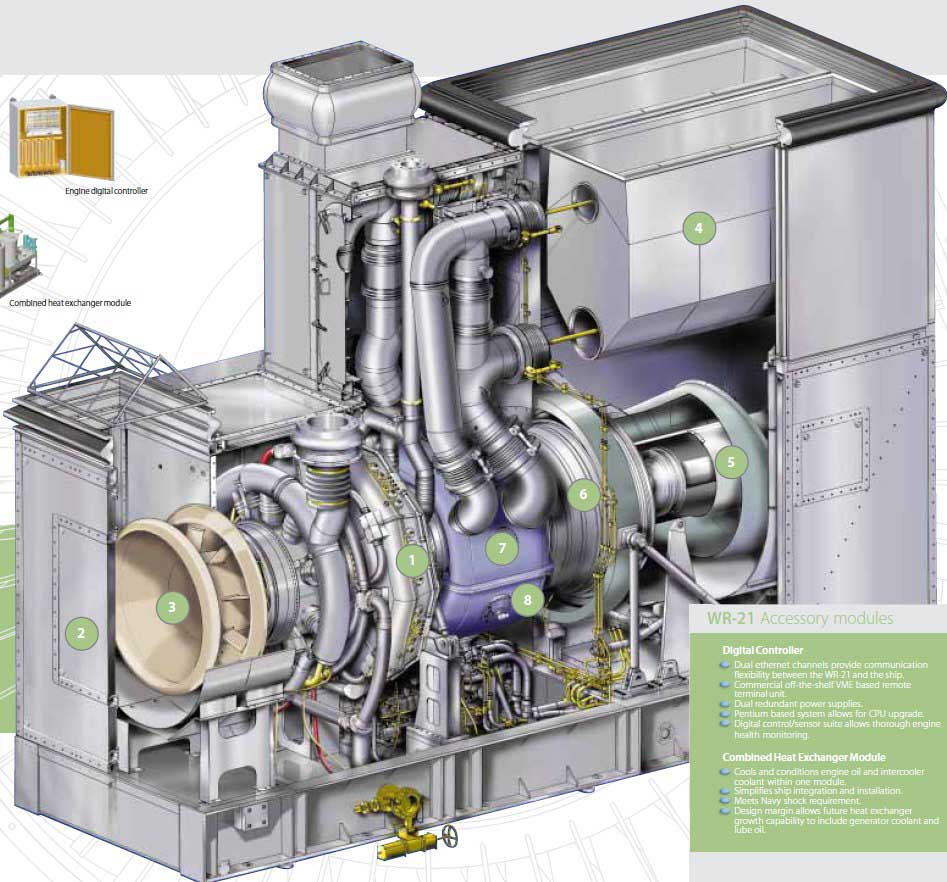

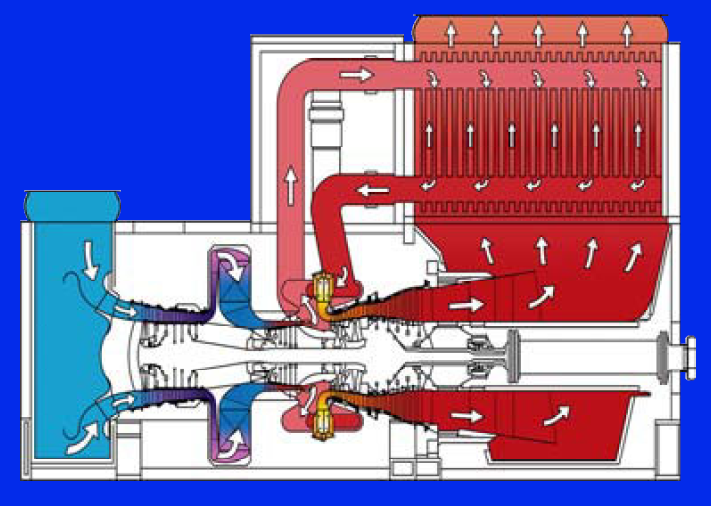

During the verification test the durability of the recuperator was questioned but solved by changing materials and commercialized. WR21 gas turbineThis is the engine produced by Rolls-Royce for marine applications and stranger to rail applications considering its size and output. But this is the good example of high efficiency gas turbine. The large volume is due to the recuperator, intercooling system and the length of the package is 8 meters height is 4.83 meters, width is 2.64 meters. It weighs nearly 46 tons. But its rated output is about 25 MW, 1/6th in size compared to the comparable diesel. In such a class, gas turbine is far more advantageous than diesel in spite of adding additional devices to improve fuel economy.

The next schema shows the gas flow of this engine.

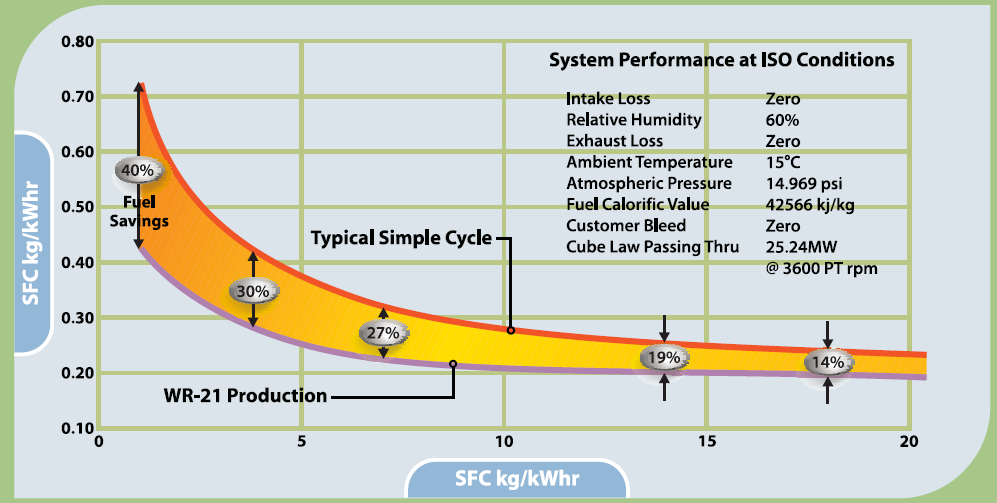

The next schema shows the partial load efficiency

comparing a simple cycle gas turbine. The title of the X-axis SFC is

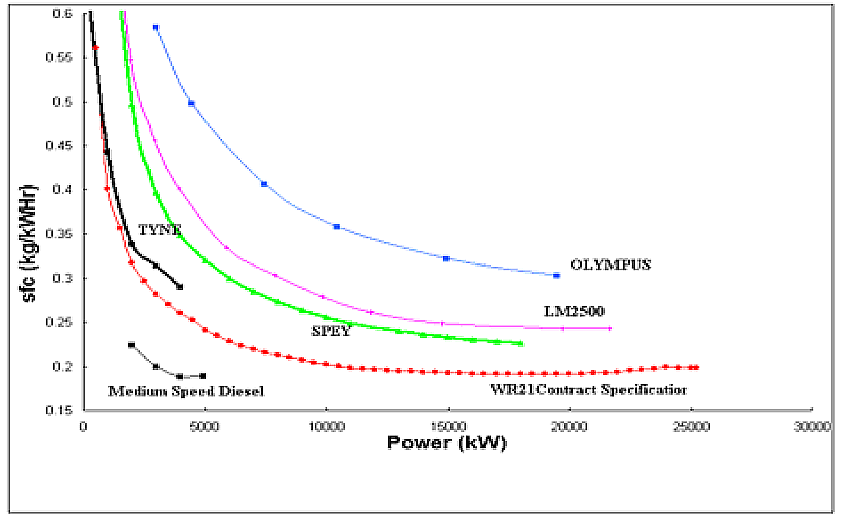

error and it should be Output (MW). At the low output range, the intercooled regenerative system works better. The next plot is the comparison of other engines.

|

.png)

.png)

This

gas turbine was also made for combat vehicles of U.S. Army by Honeywell.

The application was more small vehicles than LV100, the output was about

600 horse power, size was 147 cm

x 46cm x 66cm and 0.32 cubic meters in volume. It was very

compact for a recuperated gas turbine. The rotational speed of the power

turbine and the total weight of the generator system was 313 kg. Two-shaft

free turbine also enabled direct driving of vehicles. 1 ton or more weight

reduction was achieved in comparison to diesel generator in same output

and suitable for hybrid vehicles in future.

This

gas turbine was also made for combat vehicles of U.S. Army by Honeywell.

The application was more small vehicles than LV100, the output was about

600 horse power, size was 147 cm

x 46cm x 66cm and 0.32 cubic meters in volume. It was very

compact for a recuperated gas turbine. The rotational speed of the power

turbine and the total weight of the generator system was 313 kg. Two-shaft

free turbine also enabled direct driving of vehicles. 1 ton or more weight

reduction was achieved in comparison to diesel generator in same output

and suitable for hybrid vehicles in future.