|

|

Advanced Locomotive Propulsion System |

|||

|

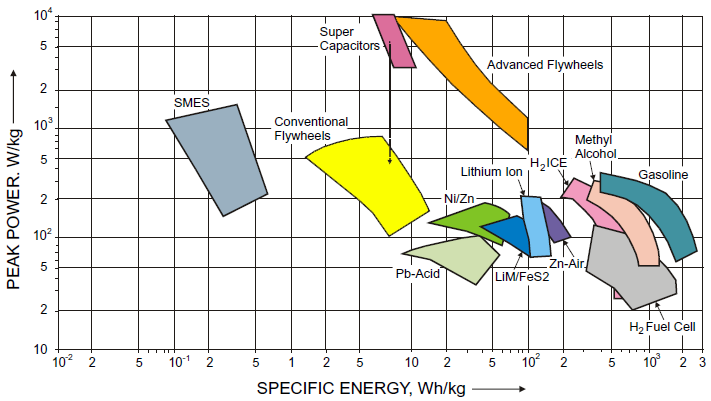

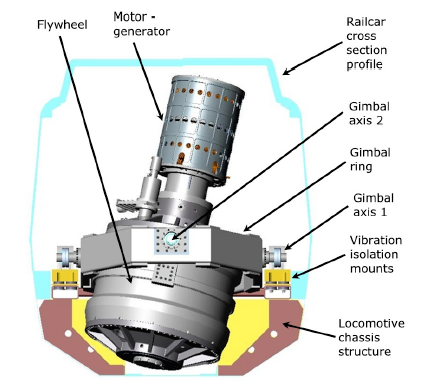

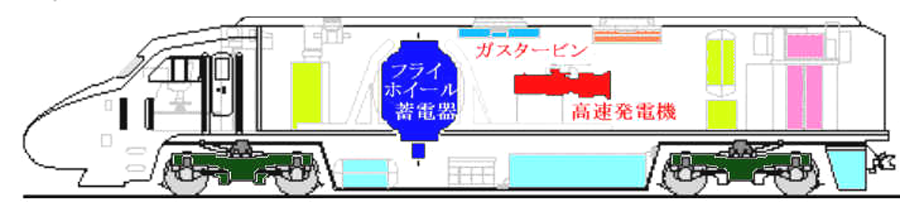

Next Generation High Speed Rail ProgramALPS (Advanced Locomotive Propulsion System) is the name of the locomotive system designed for next generation high speed rail program to realize high speed services on non-electrified lines with low cost of infrastructure. 240 km/h service and high acceleration capacity were targeted on conventional lines with turbine powered and regenerative locomotives. BatteryThe most unique mechanism of this system was the high capacity and high power flywheel battery to regenerate the train's kinetic energy. In automobiles, a regenerative system had began to be common by using chemical batteries known as "hybrid car" like Toyota Prius. But ALPS was the unprecedented scale. The system was also intended to apply military vehicles and vessels where the hybridized electric propulsion was expected as the future motive power. To enable high capacity and high peak output, a flywheel energy storage was selected instead of a chemical battery. In those days a chemical battery had poor performance or was very expensive to apply such a large scale storage. A flywheel energy storage system uses the high speed spinning rotor and directly coupled high speed motor/generator. So that it stores energy as kinetic energy and the environmental temperature has negligible impact on its performance and durability The next schema illustrates the performance of various energy storage devices. The vertical represents the available peak power per kg, the horizontal axis represents the electric energy per kg. More right position on the graph means long time supply of energy and upper position means higher immediate output. 、

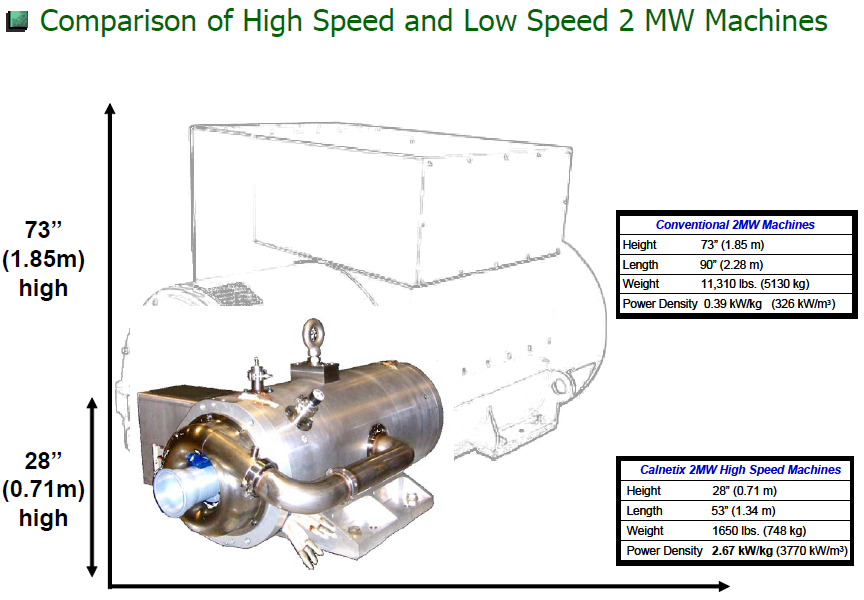

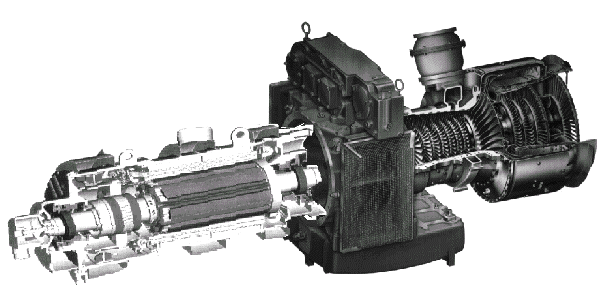

High speed alternatorMore high speed rotation, lighter. Recent technologies have realized very light weight and high efficient alternators and this has made the electric transmission more lighter and efficient than the hydraulic transmission. The efficiency has achieved 90 % or more. It is still lower than the efficiency of directly driven mechanical transmission but the optimum operation of the engine can be available in the electric drive system and will reduce the fuel consumption especially in gas turbine application. The next image is the comparison with 2000 kW conventional alternator and 20000 rpm high speed alternator in size.

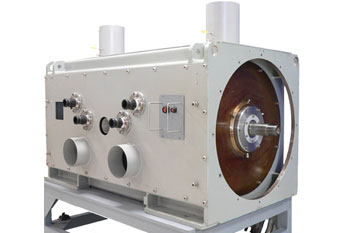

This high speed alternator achieves the efficiency of 97.5 %. The next image is 8000 kW high speed

alternator. 、 The below left image is the conventional motor of 10 MW output and the right is 8 MW high speed motor using the above alternator. You can understand the effect of the high speed rotation.

In ALPS project, 3200 kW 15000 rpm 1000 kg high speed alternator wa developed. Its length is 140 cm, diameter is 55 cm and total weight of the turbine generator set weighs only 1675 kg

The flywheel regenerating system and high speed turbine generator were scheduled to mount on the locomotive. But first test was planned to use JetTrain with conventional speed generator and flywheel regenerative system would be mounted on the separated trailer car behind JetTrain.

But there has been no further testing and development as of today and project . |