|

|

Low emission turbine powered locomotive |

|

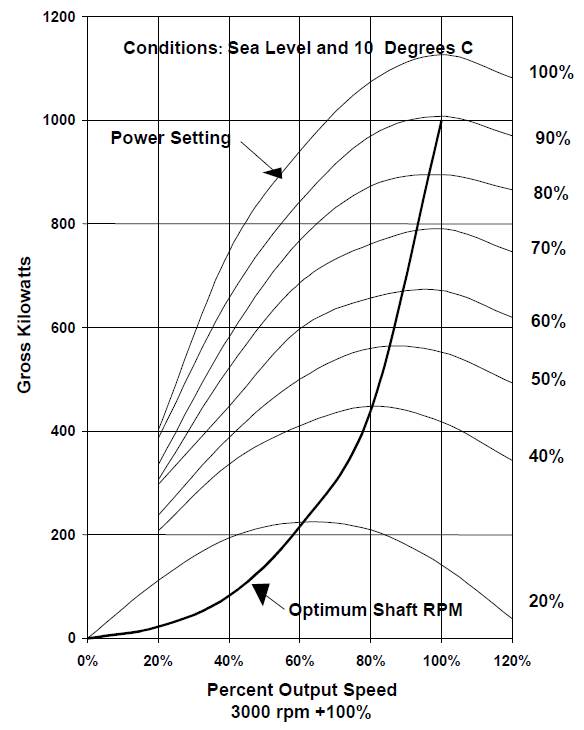

It has been already the visions of the past in Japan, there are many diesel locomotive hauled passenger train in the city area and their exhaust problems are still serious. The article proposing the solution of this problem was issued in 2002. Engine selectionThe technology to reduce high performance diesel pollutants is still incomplete and to reduce air pollution, gas turbine is a strong candidate for this purpose. But the recent high efficient gas turbines for helicopters are very expensive and it is impossible to apply to a locomotive. To avoid this problem, TF15 gas turbine was investigated. This is the same engine mentioned in the page "Facts M1 Abrams revealed" AGT1500. It is mass produced over 11000 and completely overhauled engines can be available at less than half the cost of a new engine with the same level of performance and efficiency. Conventional diesel electric locomotive throttle control is divided into 8 notches excluding the idle position. the digital engine control unit can be programmed to deliver the same power response to throttle notch position as shown in the next graph. The graph also includes an optimum speed curve. The intersection of this curve with each power setting represents the turbine speed which will deliver optimum efficiency for the power demand.

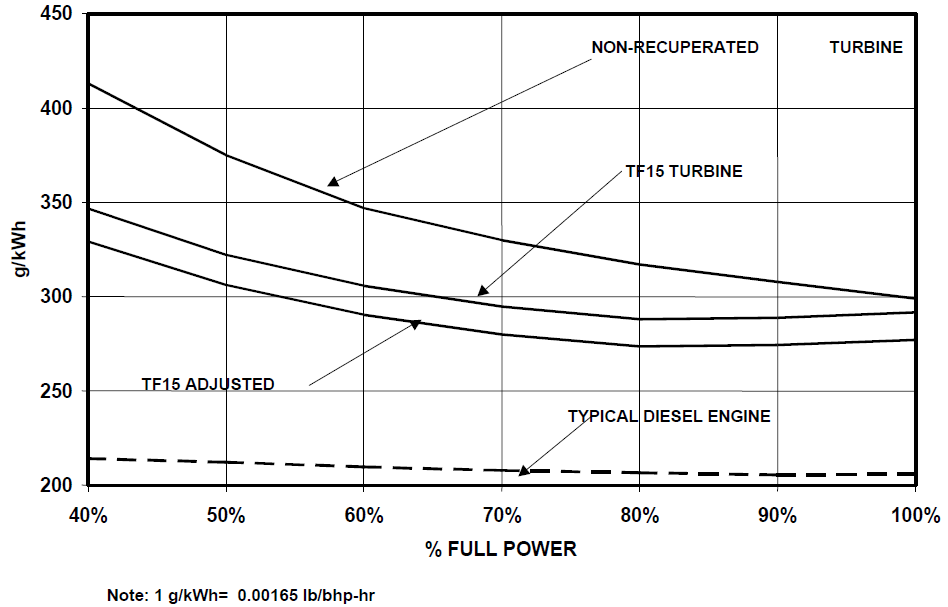

The train is assumed to have an empty weight of 675 tons and a seated load of 796 tons. Crush load is 1004 tons. Where train weight is a factor in this work, the seated load will be used as representative of average daily experience. The locomotive power train consists of a 12 cylinder, two stroke cycle, 3000 horse power diesel engine driving a 10 pole alternator at 800 rpm which in turn delivers 700 V DC of rectified power to drive four DC traction motors The next table is the percentage distribution table of the notch position used in the actual commuter line. The percentage maximum notch position is used only 26% and unfavorable conditions for a gas turbine. TF15 (AGT1500) is 1689 mm (66.5 in.) long, 991 mm (39 in.) wide and 808 mm (31.8

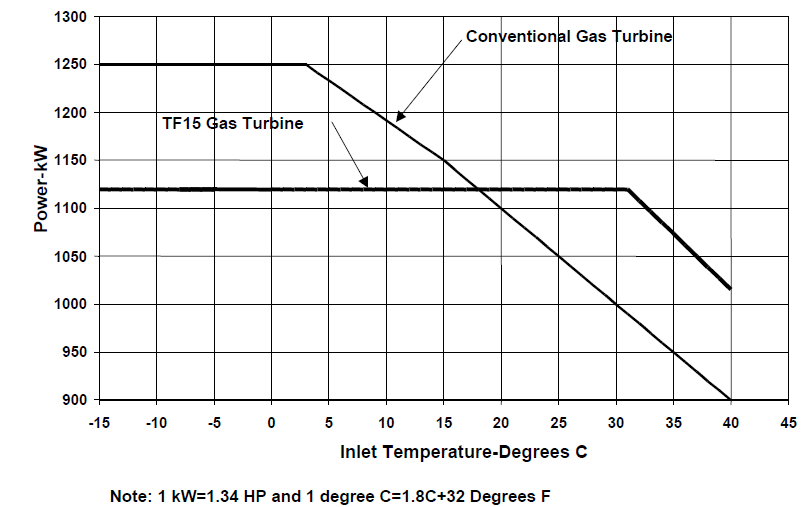

in.) high. It produces 1120 kW (1500 hp) for a weight of 1134 kg (2500 lbs.),

50.99kW/kg (0.6 hp/lb). A typical locomotive diesel produces about 0.024 kW/kg (0.07

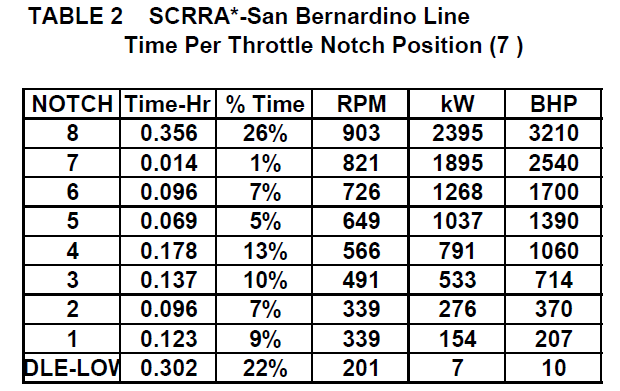

hp/lb). Output speed is 21,700 rpm reduced to 3000 rpm by a planetary gear train. The next graph shows the specific fuel consumption as a function of power output for

the TF15 as well as for a typical diesel engine and a non-recuperated, or conventional,

gas turbine of similar size.

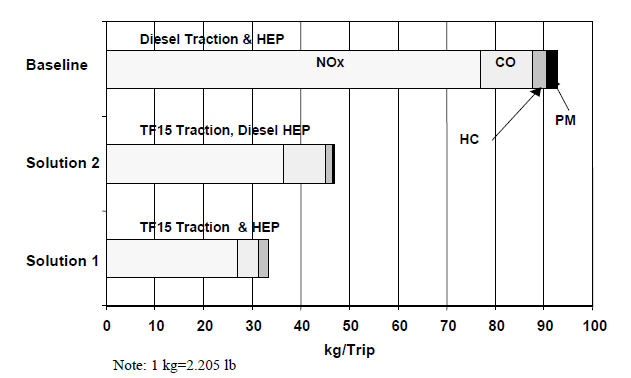

EmissionThe next schema shows the comparison of three types.

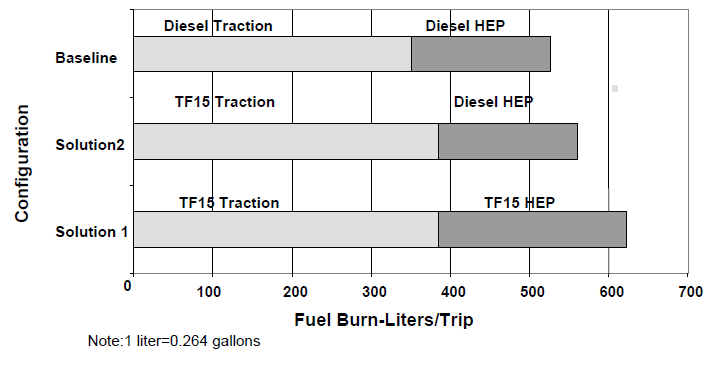

Fuel consumptionThe fuel consumption increases by replacing with the gas turbine.

As a result, this replacement produces a 50% reduction in emissions for a 7% increase in fuel consumption. LNG as an alternativeLNG offers an alternative to diesel #2 fuel oil for internal combustion engines.

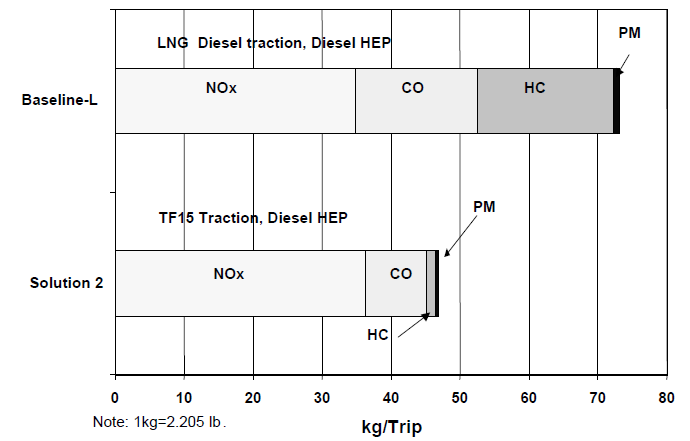

But there are some problems. The next figure is a bar chart comparing the emissions per trip for the diesel locomotive LNG conversion and the diesel#2 fueled TF15 locomotive.

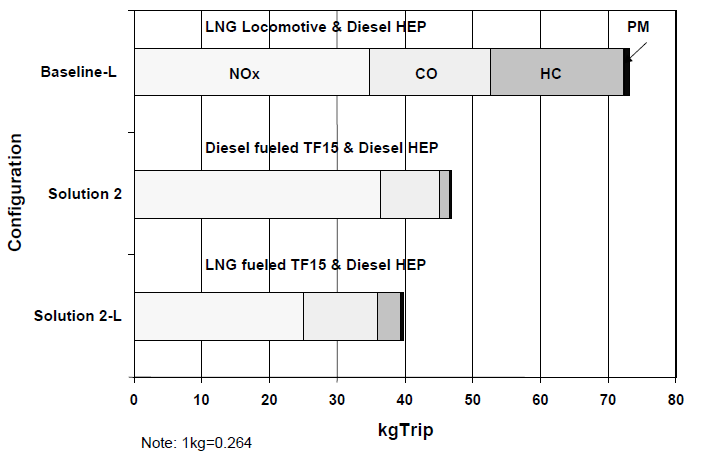

Note that nitrous oxide (NOx) emissions are about the same for both configurations but that the Solution 2 total emissions are 26 kg (36%) lower than the LNG diesel locomotive as a result of lower carbon monoxide (CO) and hydrocarbon (HC) emissions. The next graph is the direct comparison of three configurations.

|